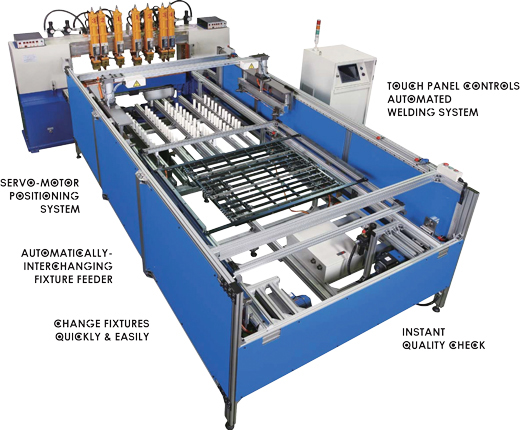

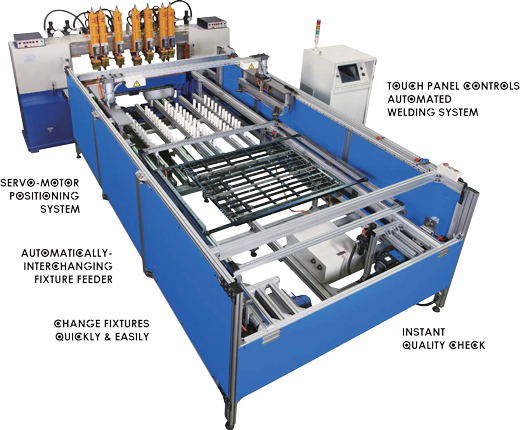

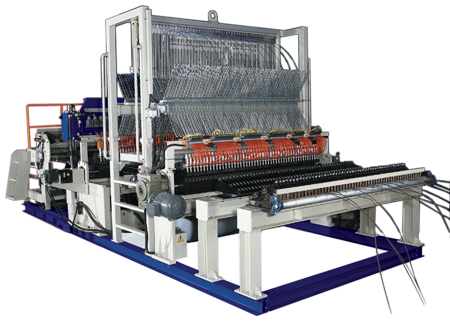

SA-AF Series

| The SA-AF Dual-Layer Multi-Spot Mesh Welder welds more parts with less labor. Lower your costs and increase your profits with the SA-AF Mesh Welder. |

The SA-AF Dual-Layer Multi-Spot Mesh Welder welds more parts with less labor.

Lower your costs and increase your profits with the SA-AF Mesh Welder.

FEATURES:

- Automatic dual-layer machine interchanges feeding and welding simultaneously.

- Configuration allows you to change fixtures quickly and easily.

- Perfect for high volume production environments.

- Average Speed: 2 parts per minute.

- Customization available to suit your application.

- Microprocessor-based welding control with touch-screen

interface makes programming simple. - Golden Spot ™ Service First Policy guarantees superior

quality and value backed. Applications: • Animal Containment: Cages and Enclosures... • Display Equipment: Display Racks, Stands... • Wire Mesh Products: Wire Grid, Mesh Decks, Wire Baskets for closets, Shop Fittings, Computer Enclosures... • Storage and Warehousing: Wire Storage Baskets, Mesh Stillage, Pallet Cages, Box Trailer Sides, Pallet Boxes, Storage Shelving, Storage

Containers, Tool Racks...

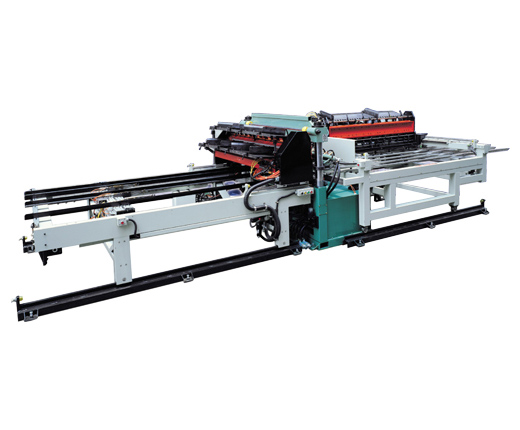

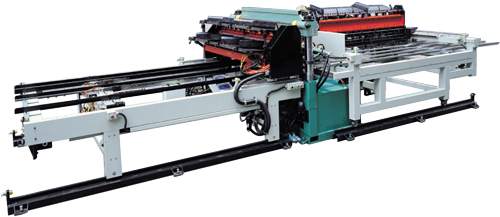

GSA-80

The GSA-80 High Speed Wire Mesh Welder is designed for energy savings, and built to last.

Applications include: Wire mesh for furniture, wire shelving, industrial mesh, grills, mesh decks, pallet decking, display equipment, stillage mesh, box trailer sides, wire containers, storage shelving, material containers, tool racks, storage and warehousing.

FEATURES:

- High-Productivity: 0.6 sec/cross wire

- Superior flexibility for producing the most different type and

sizes of wire mesh with fast and simple change-over. - Modular System offers versatility, allows for future additions and retrofits.

- Output Section: mounted on servo motor, gripping pliers move based

on the pitch set, carrying the welded mesh to the next work station. - Welding Section: based on the wire pitch, the machine can adjust

upper cylinders, electrodes and gripping pliers.

Fully adjustable welding parameters (time, current, etc.) - Infeed Section: Automatic wire loading carriage with single/dual wire hopper

for loading pre-cut wires, machine will auto-order and eject wires

into the V-shaped guiding rails. Rails are adjustable depending on wire pitch. - Machine Control System: The HMI (Human-machine Interface) links with P.L.C.

All parameters are set using the touchscreen. Easy to operate and maintain.

| MODEL | Line Wire Length | Cross Wire Length | Wire Diameter | Line Wire Pitch (mm) | Cross Wire Pitch (mm) |

|---|---|---|---|---|---|

| GSA-80/1200 | 600-1800 mm | 600-1200 mm | 3-8 mm | ≧25 | ≧15 |

| GSA-80/1800 | 600-1800 mm | 600-1800 mm | 3-8 mm | ≧25 | ≧15 |

GSV-80

The GSV-80 is a Vertical-type Wire Mesh Welding Machine, 80 KVA.

Applications include: Wire mesh shelving, wire grille, wire mesh for construction, security fencing, etc...

FEATURES:

- Pre-cut cross wires automatically feed. 0.6 sec/crosswire

Feed Rate allows for high-speed production. - Quick and easy setup and change-over allow welding differently-sized wire mesh.

- Output Section: mounted on servo motor with grippers, the machine removes

welded wire mesh from the machine with no accumulative tolerance problems. - Welding Section: based on the wire pitch, the machine can adjust upper cylinders,

electrodes and gripping pliers. Fully adjustable welding parameters (time, current, etc.). - Infeed Section: Manually loaded rail feeds 1-2 pieces of frame from both sides toward

welding position. Automatic cross-wire loading carriage with single wire hopper for sorting,

positioning and ejecting pre-cut wires. - Machine Control System: The HMI (Human-machine Interface) links with P.L.C.

All parameters are set using the touchscreen. Easy to operate and maintain.

| MODEL | Frame Height(mm) | Cross Wire Length | Wire Diameter | Line Wire Pitch (mm) | Cross Wire Pitch (mm) |

|---|---|---|---|---|---|

| GSV-80/1200 | ≦700 | ≦1200 mm | 3-8 mm | ≧75 | ≧15 |

GSA-125C / GSA-200C

| Applications include: shell structure, wall structure, reinforced concrete mesh, retaining wall reinforcement, floor boards, welded wire fencing, barrier fence, metal fence, fine mesh, fence netting, welded nets, temporary fencing, security fence, safety fencing, safety/security enclosures, security barriers, prison mesh, prison security fencing, rigid mesh, wire mesh partitions, construction fence, concrete meshes, prefabricated steel reinforcing material, fabricated stainless steel wirework, welded mesh fabric, steel wire mesh, engineered mesh, steel fabric mesh, welded screens, electrowelded steel wire mesh, etc... |

FEATURES:

- Insert line wires off coil to the wire feeding device, then send to

the wire accumulator via 2 sets of wire straightening devices by driven motor,

according to the required distance precise adjustment of the wire pitch. - Automatic cross wire loading with cross wire hopper for sorting,

positioning and ejecting straightened, cut to length wires. - According to the wire welding pitch, the machine can adjust upper cylinders

and electrodes. Each welding point is adjustable

and controlled by water cooled SCR and micro-computer timer for precise weld control. - Wire Straightening Device: 2 sets of the device for straightening the wires.

- Wire Feeding Device: 2 sets of wire feeding device; one is driven

by the converter motor to send the wires to the wire accumulator,

another is driven by the servo motor to send the wires to the welding machine.

Both of them aid in precise pitch control. - Welding Device: based on the wire pitch, the machine can adjust upper cylinders,

electrodes and gripping pliers. Fully adjustable welding time and current. - Cross Wire Carriage: automatic cross wire loading carriage with single wire hopper for sorting,

positioning and ejecting straightened and cut to length cross wires. - Controlling System: P.L.C with color man-machine interface window

where all the parameters of the system are set on the screen.

Complete fault diagnostic system with pictures to resolve error efficiently.

Linking with P.L.C, the working process and fault messages are graphically presented. - Fault Examination: Wires supply, non-wires, fault of line wires discharging,

fault of cross wires ejecting, line wire forwarding, short of welding power,

overloaded of servo motor, fault positioning, fault of air compressor, over-high temperature. - Peripheral Device: Re-coiler device- applicable for wire 3-5mm.

Guillotine Shear- applicable for wire 3-8mm and smaller than 12mm.

| MODEL | Line Wire Length | Cross Wire Length | Wire Diameter | Line Wire Pitch (mm) | Cross Wire Pitch (mm) |

|---|---|---|---|---|---|

| GSA-125 | Unlimited | 1000-2400 mm | 3-6 mm | ≧100 | ≧50 |

| GSA-200 | Unlimited | 1000-2400 mm | 6-12 mm | ≧100 | ≧50 |